Building Energy Management Systems

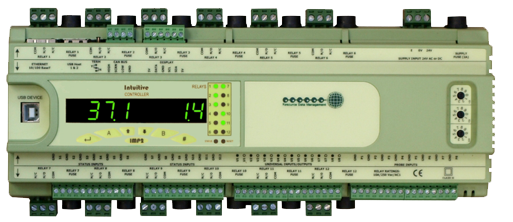

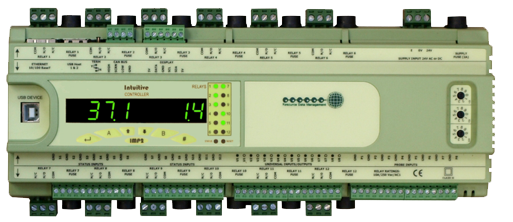

Information collected by sensors located in your building(s) are sent to the Touch Panel Controller. This information is processed into comprehensive data which is displayed in various easy-to-read formats ready for the appropriate control or task, either requiring a manual input or, if required, an automatic adjustment.Full control of your site from anywhere in the world via a smart phone/tablet/PC etc.

Information collected by sensors located in your building(s) are sent to the Touch Panel Controller. This information is processed into comprehensive data which is displayed in various easy-to-read formats ready for the appropriate control or task, either requiring a manual input or, if required, an automatic adjustment.Full control of your site from anywhere in the world via a smart phone/tablet/PC etc.

Our Unique Building Energy Management system (BEM) is easily fitted to any building, either as a new system or working alongside your existing BMS or Control system. It can operate and monitor all of your buildings equipment while keeping you in complete control, utilising programmable operating times, remote access with efficiency controls and monitoring diagnostics. The BEM can control ALL or individual items of equipment, such as;

- Lighting

- HVAC

- Refrigeration

- Sub Metering

- Security Panels

And Much More!

Our BEM uses an Open System protocol so you can continue to use your existing equipment without being forced to switch or replace to update equipment if so desired.

Our BEM uses an Open System protocol so you can continue to use your existing equipment without being forced to switch or replace to update equipment if so desired.

The BEM can be used for any size of project with all features readily available, regardless of site size..

Business benefits, including slashed energy costs and improved overall management, can't help but result in further savings and improved productivity.

The BEM is a future proofed system. Being "legacy equipment compatible" enables integration into any future systems or equipment you may be planning on installing at a later date.

The BEM is a future proofed system. Being "legacy equipment compatible" enables integration into any future systems or equipment you may be planning on installing at a later date.

A fully modular system which can be expanded at any time to suite any growing building or site:

- Open communications IP protocol

Freedom to choose parts of the system from different sources

- Easier to integrate & adapt to future innovations

- Web based browser accessed via Smart phone/Tablet/PC

- No proprietary access software required. No annual licence fees

- Global, multi-point accessibility

An easy to use interface with simple and transparent readouts which provides you with complete control of your facility, you can access the system to look at any data point and check its current operation.

An easy to use interface with simple and transparent readouts which provides you with complete control of your facility, you can access the system to look at any data point and check its current operation.

You can make any and all adjustments, turn equipment on/off or set a time or power consumption limit should you need. Alternatively, simply change the value of a thermostat all from the comfort of your personal smart phone, tablet or device.

By gaining visibility of everything that is using energy, including water, you can control and monitor your usage charges and eliminate excessive wastage before it occurs.

- The data from different systems can be used to influence operational actions.

For example, sharing HVAC Humidity data to influence trim heater controls

Integration allows the modifying of control strategies. Also, adding new control strategies and data points will increase operational efficiencies.

The BEM can communicate with your existing equipment then relate and compare this info with another area that perhaps was not previously monitored. The BEM will then use this additional information to best achieve the most cost effective desired results.

- System visibility helps to locate and identify problem areas if there are many systems operating in isolation and conflicting with other systems. This conflict only usually shows up in the utility bills or poor functionality.

With real time monitoring and control, you can maintain an automated tight grip on the efficiency and operational levels required.

If you wait until the main utility meter has recorded the higher energy consumption you have already lost the savings!

- We operate in the background 24/7/365, visible only at your discretion, both locally and remotely, for all maintenance purposes.

LED Lighting

The benefits of LED Lighting are endless including factors such as;

Microwave Sensor Emergency Lighting

Ideal for underground car-parks and

emergency stairwells

Energy Efficient

On average, they required 60% to 90% less power.

Longer Life spans

Around 5 to 6 times longer than Halogen or fluorescent lamps

Improved Durability

LED's have no filaments so can withstand a greater intensity of vibration and shock than standard lights, making them durable with less risk of breaking and need of replacement.

High Power DownLight

Ideal for foyer lighting and entrance

canopy

High bay Lighting

Ideal for high ceilings and

warehouse applications

Safer

Most LED lights operate at low voltage so are cool to touch and much safer to handle during installation and maintenance. They also operate at a much lower temperature which significantly reduces the risk of fire (especially when compared to Halogen lamps).

They can be exposed to rain and poor weather conditions.

Environmentally Friendly

An eco-friendly form of lighting as they do not contain mercury or other harmful gasses or emit any harmful UV rays.

We can update your old lighting with LEDs and introduce additional control systems such as Independent and sectored control systems incorporating a variety of timers; Lux & radar sensing technologies. We can custom-design to suit any specific area and lighting level requirements.

Retro-fit tube with microwave sensor

Ideal for big savings on small budgets

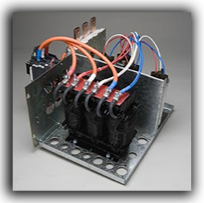

Voltage Power Optimization

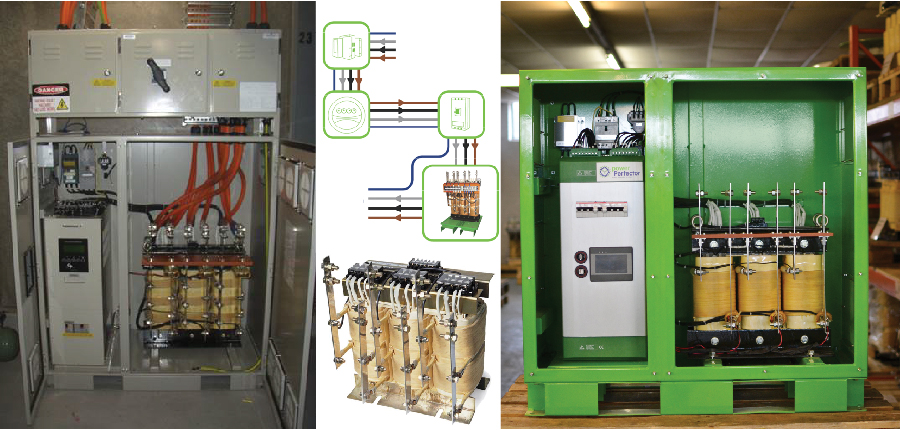

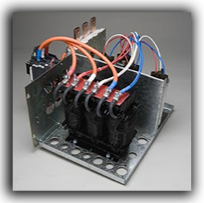

Voltage Power Optimisation Units (VPO) will achieve saving by increasing the efficiency of most of the equipment within your site, thus requiring them to use less power.

VPO units are designed to address a number of common power supply problems in a single unit. Uniquely, all these improvements are achieved through the internal interaction of magnetic fields, with no active suppression or compensation, meaning that moving parts or electronics are not required. The design is extremely efficient and its performance and reliability are unmatched by any technology available in Australia today.

The VPO has the following primary functions:

- Incoming voltage, typically around 240V for sites in Australia is brought down to an optimum operating level for most equipment, at around 220V.Equipment downstream will then consume less energy than with the over-voltage conditions normally prevalent in Australia. In motors, for example, over-voltage drives the core into saturation, which wastes energy as heat. The VPO corrects this with 99.9% efficiency across its entire operating range, so the resulting savings are not offset by energy loss in the unit itself.

- Voltages on the three supply phases are balanced by the regulating effect of the VPO’s star-connected secondary windings. Improvements in phase balancing of over 20% have been observed, which dramatically increases the efficiency of 3-phase AC motor equipment, common in refrigeration and air distribution systems.

- A harmonic filter is integrated into the design of the VPO, which attenuates the Total Harmonic Distortion (THD). As harmonics are potentially damaging to electronic equipment, and known to reduce the efficiency of HV transformers, this is an important function that delivers tangible energy-saving benefits.

- As a result of the improvements in power quality, a typical VPO installation will bring the Power Factor of a site closer to unity by 0.02 - 0.1. This may alleviate the need for additional Power Factor Correction (PFC), although the VPO is fully compatible with this type of equipment. Considerable reductions in reactive power have been achieved, reducing penalty charges from electricity suppliers.

- The VPO will protect a site from transients up to 25kV, which can have a devastating effect on sensitive electronic equipment. As transients become more common due to increased switching on the grid, this provides a vital defence for critical IT systems.

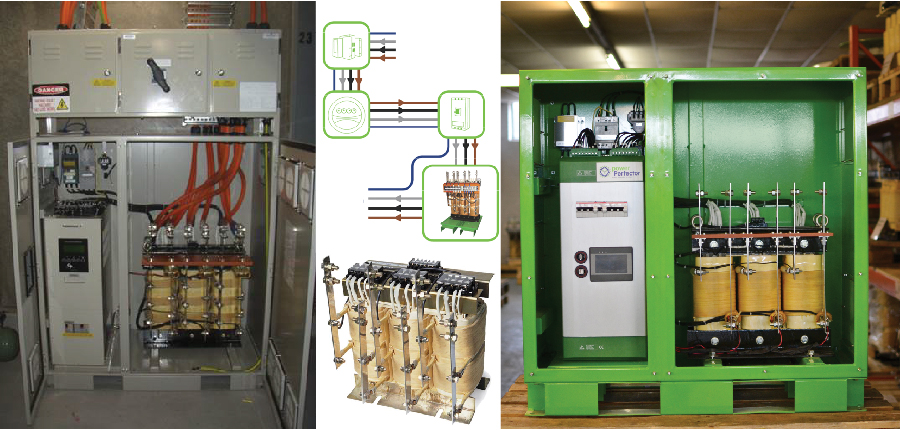

Power Factor Correction

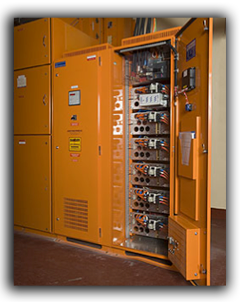

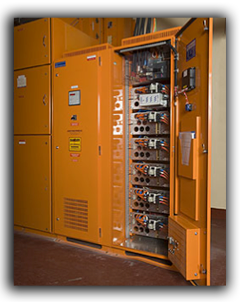

We assess the need for Power Factor Correction equipment and incorporate any design to suit the required application, ranging from small single cabinets through to large multi-cabinet designs.

We assess the need for Power Factor Correction equipment and incorporate any design to suit the required application, ranging from small single cabinets through to large multi-cabinet designs.

All Australian made and guaranteed.

The advantages of having a good power factor

The advantages of having a good power factor

- Reduce the cost of electricity

- Increase available capacity therefore making room for additional load/equipment.

- Improve efficiency.

- Improve the quality of electrical supply.

- Reduce greenhouse emissions.

Improving power factor can reduce operating costs on your electricity bill by reducing what is known as you KVA demand (Kilo Volt Amperes). You are charged per KVA per day.

Improving power factor can reduce operating costs on your electricity bill by reducing what is known as you KVA demand (Kilo Volt Amperes). You are charged per KVA per day.

However, there is also a peek demand charge and this means that whenever your highest demand occurred you will be charged at this new higher demand/rate for the duration of the billing period, usually the rest of the year.

But this, in itself, is only a small part of what having good power factor can do for your facility.

But this, in itself, is only a small part of what having good power factor can do for your facility.

When you consider the savings involved when your equipment runs more efficiently and factor in the reduced maintenance costs, the actual saving and benefits are much greater.

Solar

Here at the NRG Company we manage both small and large scale projects and consult on all aspects of the installation

We conducted feasibility studies to assess the viability of a solar system for your facility. The NRG Company will take into account the load profile of the building as this is important to correctly size the system and determine the upfront costs. The NRG Company will also evaluate both system and financial performance. Many financial scenarios change overtime such as, renewable energy certificate prices, energy price projections, energy export projections and cash flow options.

We conducted feasibility studies to assess the viability of a solar system for your facility. The NRG Company will take into account the load profile of the building as this is important to correctly size the system and determine the upfront costs. The NRG Company will also evaluate both system and financial performance. Many financial scenarios change overtime such as, renewable energy certificate prices, energy price projections, energy export projections and cash flow options.

It is important to know what you want from a solar system, for example do you want to use the energy produced to offset your electricity bill, or would you require the solar system to produce a revenue stream for you or possibly both? These factors are essential to achieve the best possible solar solution available for your facility and your needs.

The design phase is possibly the most important and there are many different solar panels and connection methods available today, some things that need to be considered; String sizes Selecting the correct string size is one of the most important aspects of PV system design. A string is multiple solar modules connected together and the number of modules in that string is its size. Systems with strings that are too small will sacrifice efficiency. Over sizing strings can damage inverters. Connecting solar modules in series is most common in grid tied systems while parallel strings are often used in small battery charging systems. Temperature and string voltage The relationship between ambient temperature and string voltage must be taken into consideration when calculating string size. An inverse relationship exists between the ambient temperature and PV array energy output. Cold temperatures will result in increased output and higher string voltage. Hot temperatures will decrease output and string voltage.

If the minimum and maximum ambient temperature is ignored while calculating string size a cold winter morning could result in over voltage to your inverter or charge controller causing it to shut down when the array is in its most efficient temperature range. On the other hand, a hot summer afternoon could cause the string voltage to drop below the maximum power range on your grid tied inverter. String sizing, charge controllers and the different types of inverters can be confusing, The NRG company is here to make sure all of your system components are compatible with one another. These are just some of the design characteristics that we here at the NRG company will engage upon to deliver the most efficient solar system to you.

If the minimum and maximum ambient temperature is ignored while calculating string size a cold winter morning could result in over voltage to your inverter or charge controller causing it to shut down when the array is in its most efficient temperature range. On the other hand, a hot summer afternoon could cause the string voltage to drop below the maximum power range on your grid tied inverter. String sizing, charge controllers and the different types of inverters can be confusing, The NRG company is here to make sure all of your system components are compatible with one another. These are just some of the design characteristics that we here at the NRG company will engage upon to deliver the most efficient solar system to you.

Battery Systems

There are many battery systems available in Australia today, a good battery system should provide flexibility in use. For example, a battery that can be charged by solar panels, wind generators and if necessary from the mains grid via lower-priced off-peak electricity.

In essence an effective battery can power your facility when your solar panels and/or wind generators aren't producing enough electricity or possibly, and more cost effectively be used to offset high peak demand charges.

Currently there are 2 types of batteries leading the market, Lithium and Flow Batteries

Lithium

Lithium

Lithium batteries store their energy in cells. They are relatively small, self-contained devices, they power many small electronic devise today, such as mobile phones, laptops, tablets ect.. They are now being used for much larger scale devices like electric cars and home storage uses.

Being small and having a high power output is their definite advantage. However, a major disadvantage is heat, as they have a tendency to catch on fire when temperatures start to exceed 60'c.

Companies such as Telsa have overcome this issue by creating their casing in fire proof materials. Tesla are currently building a mega factory to produce their batteries in an attempt to reduce costs. This is due to open in 2020.

Lithium batteries have a finite life. Performance degrades over time and is impacted by heat, operating conditions and how deep, and how often, they have been discharged.

Flow Batteries

Flow Batteries

A flow battery is a type of rechargeable battery where energy is stored by two chemical components are dissolved in liquids contained and most commonly separated by a membrane. The storage tanks can be fish tank size or bigger than a swimming pool, depending on the energy output required. There are different types of chemical liquids used to store electricity within the flow battery family, Zinc Bromide and Vanadium flow are currently leading the field. Both of which have outstanding lifetime charge/discharge cycles, with no loss of performance over lifetime.

It's worth noting here that Vanadium-based flow energy storage systems theoretically can operate forever.

A small down side to Vanadium over Lithium batteries, is that Lithium batteries are 85 percent efficient when new, but Flow batteries are around 75 percent efficient (for total life) This is a small price to pay considering the average lithium battery only has around 1500 charge and discharge cycles in its life time and towards the end they reduce energy output by around 50%.

A small down side to Vanadium over Lithium batteries, is that Lithium batteries are 85 percent efficient when new, but Flow batteries are around 75 percent efficient (for total life) This is a small price to pay considering the average lithium battery only has around 1500 charge and discharge cycles in its life time and towards the end they reduce energy output by around 50%.

A flow battery will keep on going at its original energy output level, just the same as when it was new.

Here at the NRG company we can consult and supply the best and most cost effective battery solution for your needs.

Information collected by sensors located in your building(s) are sent to the Touch Panel Controller. This information is processed into comprehensive data which is displayed in various easy-to-read formats ready for the appropriate control or task, either requiring a manual input or, if required, an automatic adjustment.Full control of your site from anywhere in the world via a smart phone/tablet/PC etc.

Information collected by sensors located in your building(s) are sent to the Touch Panel Controller. This information is processed into comprehensive data which is displayed in various easy-to-read formats ready for the appropriate control or task, either requiring a manual input or, if required, an automatic adjustment.Full control of your site from anywhere in the world via a smart phone/tablet/PC etc.

Our BEM uses an Open System protocol so you can continue to use your existing equipment without being forced to switch or replace to update equipment if so desired.

Our BEM uses an Open System protocol so you can continue to use your existing equipment without being forced to switch or replace to update equipment if so desired. The BEM is a future proofed system. Being "legacy equipment compatible" enables integration into any future systems or equipment you may be planning on installing at a later date.

The BEM is a future proofed system. Being "legacy equipment compatible" enables integration into any future systems or equipment you may be planning on installing at a later date. An easy to use interface with simple and transparent readouts which provides you with complete control of your facility, you can access the system to look at any data point and check its current operation.

An easy to use interface with simple and transparent readouts which provides you with complete control of your facility, you can access the system to look at any data point and check its current operation.

We assess the need for Power Factor Correction equipment and incorporate any design to suit the required application, ranging from small single cabinets through to large multi-cabinet designs.

We assess the need for Power Factor Correction equipment and incorporate any design to suit the required application, ranging from small single cabinets through to large multi-cabinet designs.

Improving power factor can reduce operating costs on your electricity bill by reducing what is known as you KVA demand (Kilo Volt Amperes). You are charged per KVA per day.

Improving power factor can reduce operating costs on your electricity bill by reducing what is known as you KVA demand (Kilo Volt Amperes). You are charged per KVA per day. But this, in itself, is only a small part of what having good power factor can do for your facility.

But this, in itself, is only a small part of what having good power factor can do for your facility. We conducted feasibility studies to assess the viability of a solar system for your facility. The NRG Company will take into account the load profile of the building as this is important to correctly size the system and determine the upfront costs. The NRG Company will also evaluate both system and financial performance. Many financial scenarios change overtime such as, renewable energy certificate prices, energy price projections, energy export projections and cash flow options.

We conducted feasibility studies to assess the viability of a solar system for your facility. The NRG Company will take into account the load profile of the building as this is important to correctly size the system and determine the upfront costs. The NRG Company will also evaluate both system and financial performance. Many financial scenarios change overtime such as, renewable energy certificate prices, energy price projections, energy export projections and cash flow options.

If the minimum and maximum ambient temperature is ignored while calculating string size a cold winter morning could result in over voltage to your inverter or charge controller causing it to shut down when the array is in its most efficient temperature range. On the other hand, a hot summer afternoon could cause the string voltage to drop below the maximum power range on your grid tied inverter. String sizing, charge controllers and the different types of inverters can be confusing, The NRG company is here to make sure all of your system components are compatible with one another. These are just some of the design characteristics that we here at the NRG company will engage upon to deliver the most efficient solar system to you.

If the minimum and maximum ambient temperature is ignored while calculating string size a cold winter morning could result in over voltage to your inverter or charge controller causing it to shut down when the array is in its most efficient temperature range. On the other hand, a hot summer afternoon could cause the string voltage to drop below the maximum power range on your grid tied inverter. String sizing, charge controllers and the different types of inverters can be confusing, The NRG company is here to make sure all of your system components are compatible with one another. These are just some of the design characteristics that we here at the NRG company will engage upon to deliver the most efficient solar system to you.

A small down side to Vanadium over Lithium batteries, is that Lithium batteries are 85 percent efficient when new, but Flow batteries are around 75 percent efficient (for total life) This is a small price to pay considering the average lithium battery only has around 1500 charge and discharge cycles in its life time and towards the end they reduce energy output by around 50%.

A small down side to Vanadium over Lithium batteries, is that Lithium batteries are 85 percent efficient when new, but Flow batteries are around 75 percent efficient (for total life) This is a small price to pay considering the average lithium battery only has around 1500 charge and discharge cycles in its life time and towards the end they reduce energy output by around 50%.